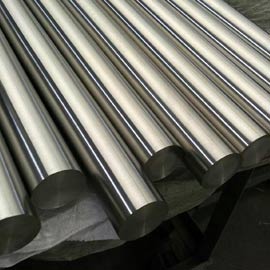

한국 스틸 라운드 바 제조사

Nickel alloys are some of the few metallic materials that can be used in contact with fluorine, hydrofluoric acid, hydrogen fluorine, or other derivatives. These nickel bars show very high resistance to caustic alkalies. Behavior in seawater is also excellent, with improved resistance to cavitation corrosion compared to copper-based alloys. It can be used in contact with dilute solutions of mineral acids, such as sulphuric and hydrochloric acids, particularly if they are air-free. However, if the alloy contains no chromium, corrosion rates may increase significantly in oxidizing conditions.

The pure Nickel alloy bars manufactured by Deutsche Nickel GmbH include the grades NR-Ni 99 (Alloy 201, 2.4068), R-Ni 99.2 (Alloy 200, 2.4066), BR-Ni 99.6 (2.4060) and LC-Ni 99.6 (2.4061), all with chemical composition in accordance with DIN 17740.

These alloys are resistant to the corrosive influences of most media and are impervious to severe corrosion types, such as pitting and intercrystalline corrosion.

Due to its low Carbon content, LC-Nickel 99.6 exhibits a high resistance to corrosion caused by caustic alkalis, even at elevated temperatures. Consequently these alloys are used in chemical equipment and pressure vessels, as well as in machinery and plant manufacturing.

| Alloy | DN-Trade Name | Material-No. | UNS-No. | ASTM Specification | DIN Specification |

| 200 | R-Nickel 99,2 | 2.4066 | N02200 | ASTM B160 | DIN 17740 |

| 201 | NR-Nickel 99 | 2.4068 | N02201 | ASTM B160 | DIN 17740 |

| Ni99.6 | BR- Nickel 99.6 | 2.4060 | DIN 17740 | ||

| LC-Ni99.6 | NR-Nickel 99.6 | 2.4061 | DIN 17740 |